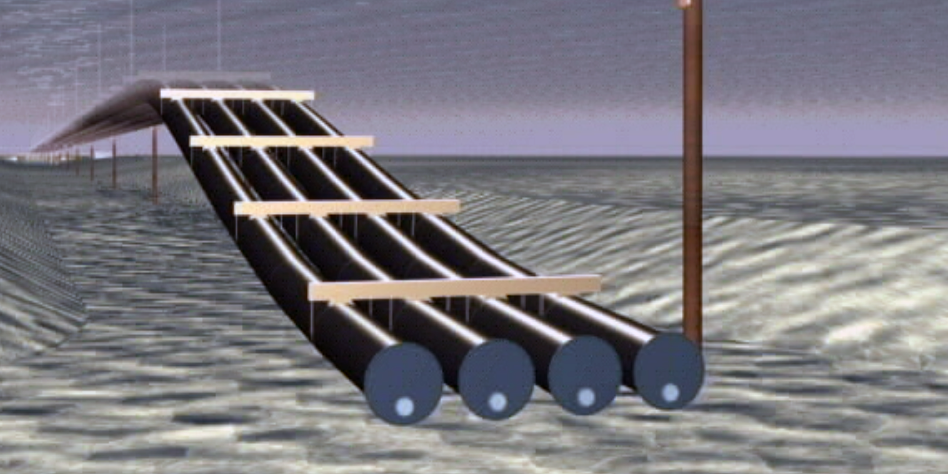

Advanced Digital Twin Solutions for Onshore & Offshore Oil & Gas

At Orcintech, we develop high-fidelity digital twins for onshore and offshore oil and gas assets, enabling real-time monitoring, predictive analytics, and operational optimization. Our AI-powered digital twin platform integrates SCADA systems, IoT sensor networks, edge computing, and cloud-based data analytics to create an interactive, real-time representation of oilfield assets. By leveraging physics-based simulations, machine learning (ML) algorithms, and computational fluid dynamics (CFD) modeling, our solution enhances decision-making, reduces downtime, and optimizes production efficiency.

Technical Architecture of Our Digital Twin Platform

Our digital twin solutions are built on a multi-layered architecture, incorporating:

- Data Acquisition Layer: Real-time data ingestion from pressure sensors, flow meters, temperature probes, vibration sensors, and acoustic monitoring systems deployed across pipelines, drilling rigs, and FPSOs.

- Edge Processing Layer: AI-enabled edge computing nodes process sensor data locally, reducing latency and bandwidth costs while enabling real-time anomaly detection.

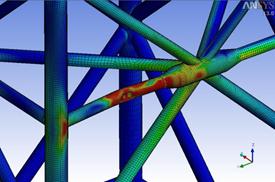

- Simulation & Predictive Analytics Layer: Advanced finite element analysis (FEA), computational fluid dynamics (CFD), and machine learning (ML) models analyze asset integrity, fluid flow behavior, and structural stresses.

- Visualization & Control Layer: A high-resolution 3D digital replica with augmented reality (AR) and virtual reality (VR) support allows engineers to interact with real-time data, simulate operational scenarios, and conduct remote inspections.

Virtual Case Study: Offshore Platform Predictive Maintenance & Production Optimization

An oil and gas operator in the North Sea faced recurring compressor failures on an offshore production platform, leading to $3.8 million in annual downtime costs. Orcintech deployed a real-time digital twin, integrating sensor data from vibration, temperature, and pressure transducers installed on the platform’s centrifugal compressors.

Using multi-sensor fusion and deep learning anomaly detection models, our digital twin identified subtle harmonic distortions in vibration signals, indicating bearing degradation well before failure occurred. A digital twin-driven predictive maintenance model suggested replacing the affected bearing several weeks before a catastrophic failure, preventing an unplanned shutdown and saving $2.1 million in maintenance and production losses. Additionally, by implementing CFD-based process optimization, the operator achieved a 7.4% increase in production efficiency by adjusting gas flow rates and choke valve settings based on real-time simulation feedback.

Key Technical Benefits of Orcintech’s Digital Twin Technology

✔ Real-time Sensor Integration: Supports Modbus, OPC-UA, MQTT, and industrial IoT protocols for seamless integration with existing SCADA and DCS systems.

✔ AI-Powered Predictive Maintenance: Leverages LSTM-based time series forecasting, reinforcement learning models, and digital signal processing (DSP) for failure prediction.

✔ Structural Health Monitoring (SHM): Uses finite element models (FEM) and acoustic emission analysis to detect pipeline corrosion, fatigue cracks, and structural anomalies.

✔ Advanced Reservoir & Well Performance Modeling: Integrates history-matched reservoir simulations, nodal analysis, and artificial lift optimization to maximize hydrocarbon recovery.

✔ Remote Operations & Augmented Reality (AR) Support: Digital twins enable real-time remote inspections, AI-assisted decision-making, and AR-guided field maintenance for offshore platforms.

By implementing Orcintech’s digital twin technology, oil and gas operators can increase equipment uptime, reduce OPEX, optimize production strategies, and ensure regulatory compliance. Contact us today to future-proof your operations with AI-driven digital twin solutions.